Graphene ink may be used to fight coronavirus

Zen Graphene Solutions (TSXV: ZEN) announced that it has launched an international collaboration with UK-based Graphene Composites to fight the covid-19 pandemic.

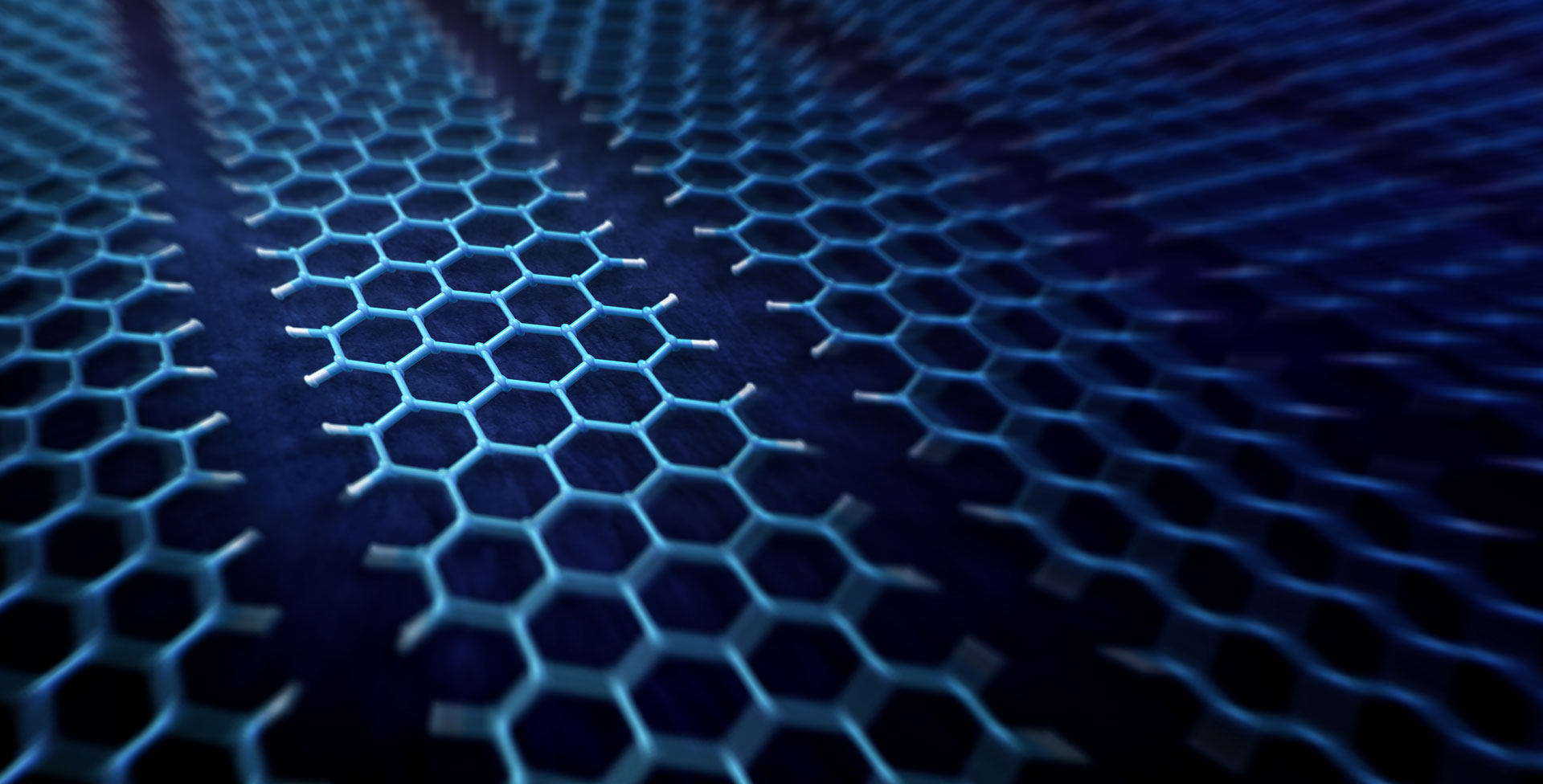

The initiative involves the development of a potential virucidal graphene-based composite ink that can be applied to fabrics, including N95 face masks and other personal protective equipment for significantly increased protection.

PPE used in the covid-19 pandemic. (Reference image by AlamosaCounty PublicHealth, Flickr).

ACCORDING TO THE COMPANY, RESEARCHERS HAVE PROVEN THAT THE INK IS EFFECTIVE IN KILLING EARLIER STRAINS OF CORONAVIRUS

In a press release, the companies said that once the development, testing, and confirmation of the graphene ink’s virucidal ability have been completed, the ink will then be incorporated into fabrics used for PPE.

Zen’s contribution to the project is based on the synthesis of a silver nanoparticles-functionalized graphene oxide ink at its lab in Guelph, Ontario. According to the company, researchers have proven that the ink is effective in killing earlier strains of coronavirus.

In recent weeks, Zen started to engineer processes for the manufacturing of products based on its trademarked Albany Pure Graphene, which is sourced from graphite extracted at the Albany deposit in Ontario.

Testing of the substance’s ability to kill SARS-CoV-2 will be conducted at Western University’s ImPaKT Facility Biosafety Level 3 lab in Ontario. In addition, the graphene ink will be tested to kill influenza A and B viruses at Biosafety Level 2 labs in the UK and US.

“The development of this potential covid-19 virucidal graphene ink is coming at a crucial time to provide effective PPE supplies for the safety of frontline workers and hospital staff,” Francis Dubé, Zen’s CEO, said in the media brief.

“The current N95 masks trap the virus but don’t kill it. Our testing will demonstrate if the graphene ink is an effective virucide which would kill the virus as this could make a big difference to people’s safety. We have been very impressed by the Graphene Composites team and look forward to continued collaborations.”

Source: mining.com